A farm in Mali, West Africa, is stretching the boundaries of what’s possible. In a landlocked country well-known for producing Cotton, Rice Millet and Corn, the Complex Agro Industrial de Baragnouma produce fish – at a rate of 5 tons a day.

In order to maintain conditions in which the fish can thrive water has to be continually filtered and oxygenated. Water treatment takes a lot of power – at the Baragnouma complex that power is provided by solar energy.

It seems fatuous to say that the reliability of their remote power plant is paramount …but if the power were to fail for just 30 minutes, the fish would die.

It was decided at the outset, in 2014, that the farm would incorporate solar energy power provision to the greatest possible extent – though few could have foreseen the scale of its success. Ninety-eight per cent of the power requirement is met by solar energy, back-up generators providing the other two percent.

In fact there are seven off grid solar-powered electrical installations at the Complex Agro Industrial de Baragnouma which provide inexpensive sustainable energy not only for their pisciculture but also for: Chicken, Dairy, Fruit and Vegetables; a factory which produces animal feed; workers houses; and two small offices.

Fortunately sunshine is very dependable in Djoliba which is 40km from Mali’s capital, Bamako. Their investment over 6 years has exceeded a million dollars – yet these investments are lower than the cost of the diesel which would otherwise have been used. And the solar installations save more than 400 tons of CO2 emissions annually.

The carefully orchestrated infrastructure includes a Fish nursery for 20,000 Alvins per cycle of production, which are reared in 8 ponds. There are a further 14 ponds each of 1000m² for the specie Clariidae. Thirteen much larger ponds provide the habitat for rearing Tilapia. There is a recycled water requirement of 14,570 cubic metres per day with pumps working at up to 180 cubic metres per day; and top-up pumped from boreholes.

The seven Off-Grid Systems have a total capacity of 520kW. Generating a similar amount of energy using diesel would cost around $260,000 a year …add to that the cost of maintenance, transport for fuel, and depreciation of the generators and it’s easy to see how the cost savings, and power security make the solar option so desirable. And the farm operates silently – which is a bonus for the 100 or so employees who are all fully engaged with the project.

The installation was carried out by Sonikara Solar Electro – overseen by company CEO and Founder Mouctar Doucoure. Working with the support of Victron staff, it is a ringing endorsement of the technological ability of Sonikara that they have been awarded the maintenance contract to oversee this huge installation for the next five years – monitoring and maintaining the system so that it runs without missing a beat.

Anco van Bergeijk (support engineer for Victron in Africa) Mouctar Doucoure (CEO and founder of Sonikara Solar)

The Biggest standalone Victron installation provides 3-phase power to the fish and chicken food factory – which can be seen in the video below. It employs:

- 12 X 15kVA Quattro Inverter/Chargers

- 6 x Fronius 27kW Eco

- 120 x 2V/3000Ah OpzS batteries

- Color Control GX

- 300kVA genset

In 2018 a dairy was added, together with a food processing factory. Last year saw the construction of some impressive looking greenhouses for vegetable production. As each success is chalked up so more new ideas are tried the owner has ever greater plans for the future of this diverse farming model.

The latest installation powers the greenhouses, and provides water treatment and pumping, together with a heat regulation system. It employs:

- 3 x 15kVA Quattro Inverter/Chargers

- 1 x Fronius 27kW Eco

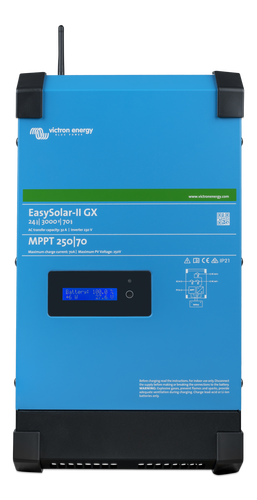

- 2 x MPPT SmartSolar 250/70

- 6 x BYD B-Box 10kW

Other installations in this large farm complex provide:

-

- 5kVA for the Egg incubators (poultry)

- 10kVA for the Poultry farm

- 60kVA for the Fish nursery and lab

- 10kVA for the Offices and Conference suite

- 10kVA Further offices

- 3kVA for Employees houses

- 3kVA for the Cattle farm

Victron products have a broad range of compatibility with third-party manufactured equipment. Fronius inverters and BYD’s Iron Phosphate chemistry batteries – chosen here for their scalability, and their ability to operate in temperatures of up to 55°C – all work seamlessly with Victron Solar Charge controllers, Inverters, and with our data-comms controller the Color Control GX (CCGX).

Using Victron’s Remote Management platform (VRM), the CCGX provides at-a-glance remote monitoring and management so that the Sonikara team can perform interventions whenever required, from their own offices.

Victron provides training and support in West Africa (and indeed all over the world) to ensure that the skills are available for projects of this scale to be built, and offers continued training to equip solar engineers with the necessary expertise.

The positive social and economic advantages are substantial and far-reaching. The farm provides fresh fish, chicken, milk and vegetables to the national and local market of Mali, Bamako. In addition to the farm’s 100 employees, it provides work for local traders, and trickle-down benefits for other commercial operators.

Mouctar Doucoure said: The challenges of an off-grid electrical project of this size is to constantly adapt to growth, and to educate all involved. We accomplished this by creating local expertise and by expanding the systems step-by-step. The quality of wiring installations, batteries, and the system design was tested after each phase. Also; all the systems can be constantly monitored online.

Let’s take a look at the site through this informative video. It’s interesting to hear a word or two about how the video was made. Seizing the opportunity to provide experience for some Video School graduates in Mali, it was decided to commission them to film and produce the promotional video below.

Much was learned and the result by Israel Oron and his colleagues – former students from Conservatoire des arts of Bamako – is excellent:

The ‘win-win’ success of this project which creates useful employment; increases education; produces healthy food in a noise and pollution-free environment; as well as reducing costs and reduces carbon emissions – is that it becomes a beacon showing the way ahead …demonstrating how technology can be harnessed for the future benefit of local communities.

All images: Photos/Film: B-Twien Clicks | Film & Photo or Ewien van Bergeijk – Kwant.

#victronenergy #adventure

#victronenergy #adventure

ELECTRICS

ELECTRICS