A 400kW hydroelectric plant near the Slovenian/Italian border had been running inefficiently for years until a third year electrical student decided to put it right as part of his coursework.

The problem was that the signalling apparatus designed to monitor the depth of the headwaters, two kilometres distant from the generator, had long since stopped operating because of numerous cabling problems along the route – resulting in efficiency losses of up to 20%.

Aleks Žvikart – who is also an intern at Victron installer Elektro Štumpfl – decided to design and build an off-grid power source at the remote headwater so that levels could be monitored remotely.

TURBINE

The Pelton turbine has a horizontal shaft; a capacity of 560kW; and is designed for smaller water-flows with large drops. The turbine is connected to a supply pipeline terminating in a nozzle which directs and controls a circular jet of water pointed at the driver blades. The power of the turbine can be regulated by moving the needle valve in the nozzle.

The task was to establish a communication between the water catchment and the power plant engine room – measuring the water level at the catchment pool, and sending this data to the engine room two kilometres away.

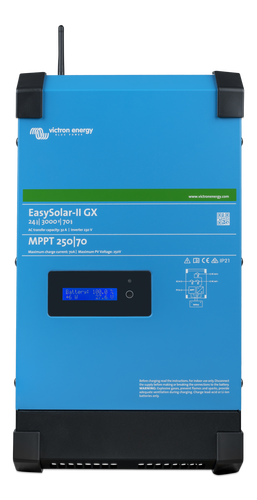

The remote distribution cabinet contains the following components at the water catchment site:

- Venus GX

- MPPT 100/30 BlueSolar Charge Controller

- Router: ROUTE 955

- SmartShunt 500 / 50mV

- Battery Protect SBP-65A

- AGM Battery (2x90Ah, 2x 110Ah 24VDC)

- Orion DC/DC Converter Tr 24 / 12-5A

- MCB circuit breakers

- BUS bus + and –

- BUS collector PE

The tidy cabinet has been divided into four sections from top to bottom:

• Active components (MPPT, Venus GX, RUT 955, SmartShunt)

• SPD, current protection, BUS busbars + and –

• Terminal blocks and BUS – PE collector

• Battery Storage

With his theoretical and practical skills Aleks was able to increase the annual production of electricity by 15-20% – whilst maintaining the renewable ethos of the system Water and Sun.

The 400kW hydroelectric power plant also has a 20 / 0.4 kV transformer station, through which it is connected to the electricity network in the nearby village of Podbela.

Engine room with built-in generator, 0.4 / 20kV power transformer; 630kVA and 20kV high voltage switchyard.

This is a very creditable piece of work from a young student. His internship at Elektro Štumpfl – who have a fifty year track record in electrical installations for Industry, Residential, and public buildings, and the manufacture of switch gear – will be a perfect opportunity for him to develop his skills and understanding of the industry.

Aleks would like to add that he planned his project using Schrack Design software which he says helped him dimension distribution enclosures and delivers the required proof of documents.

#victronenergy #adventure

#victronenergy #adventure

ELECTRICS

ELECTRICS