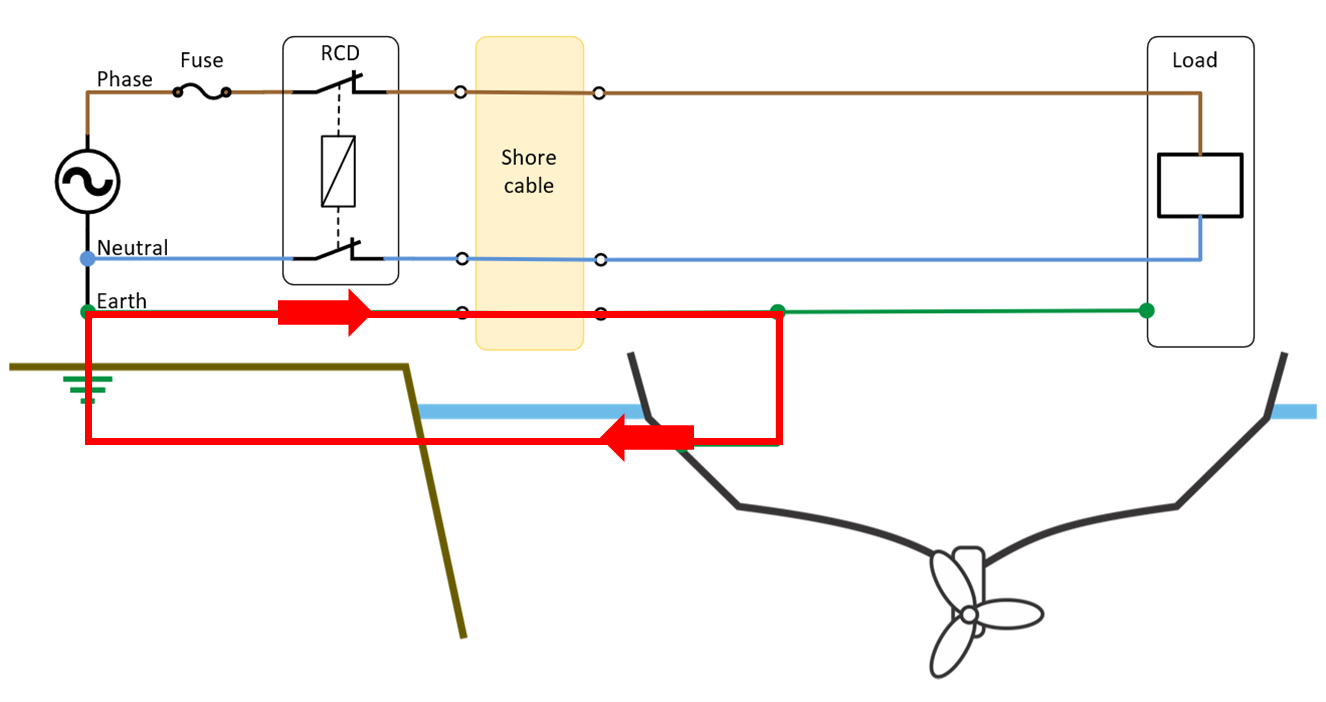

Galvanic corrosion is caused by an electric current that enters a boat via the shore power earth wire and returns back to shore via the water. These currents can cause corrosion to the boat’s underwater metals, like the hull, propeller, shaft and so on. This current is called galvanic current. Galvanic current is a DC current. It is caused by the natural voltage difference between metals. A galvanic current can only exist when there is a closed electric circuit. A conductor belonging to another electric circuit can be part of the galvanic corrosion circuit. If a boat with a metal hull is near the shore a natural voltage difference of 0.1 - 1 Vdc exists between the hull and the water. |

This potential difference leads to nothing as long there is no completion of the electric circuit. But, as soon as shore power is connected to the boat, the shore earth is automatically connected to the boat's hull and the electric circuit is complete. Now the following circuit is made: hull - water - shore - earth spike - earth wire - hull. A galvanic current will flow through this circuit. The galvanic current partly runs through the AC circuit but is not related to that circuit. Current will continue to flow until the potential difference is eliminated. The height of the current depends on the resistance of the electric circuit. The resistance is determined by factors like the length of the shore power cable and local earth spreading resistance. |  |

Chemically speaking, the “weakest” metal in the galvanic circuit will be the quickest to submit its molecules to keep the current going. If the hull of the ship is part of the galvanic circuit and the hull contains the weakest metal, the hull will start to corrode over time. This can develop into a nasty situation and it can become quite expensive and unsafe if left unchecked. There are known cases of ships that have sunk due to galvanic corrosion. Aluminium hulls are notoriously susceptible to this kind of corrosion. Galvanic corrosion can also exist between the different metals that are attached to a boat, like the propeller, the motor, the hull and so on. All these parts are connected to earth and therefore additional small currents will run between these parts. This is the reason sacrificial anodes are mounted. A sacrificial anode is a piece of metal that is weaker than the metal around it. Therefore, they are sacrificed in order to protect the other metals. They can only prevent corrosion by postponing it. What type of sacrificial anode to use, depends on the type of metal it protects and what type of water the boat is in. It is recommended to regularly check these anodes. |

The answer to prevention is quite simple. To prevent corrosion the electric circuit must be broken. Although this is nearly impossible to achieve with the small circuits between the different metals attached to the boat, it is achievable with the shore power connection. The easiest way to break this circuit is to not connect the shore earth to the hull. However, this is unsafe and not recommended, because this results in the hull being not sufficiently earthed and therefore satisfactory working of the RCD cannot be guaranteed anymore, leading to unsafe situations on board. There are safe ways to prevent galvanic corrosion without compromising safety. This can be achieved by using a galvanic isolator or by using an isolation transformer. |

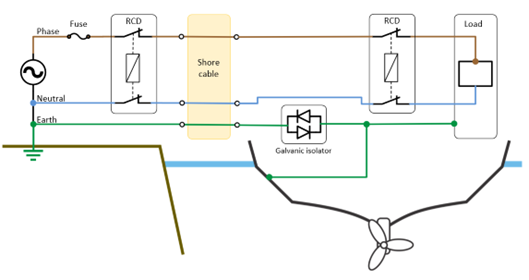

The galvanic isolator prevents galvanic corrosion. It blocks the low-voltage DC currents that enter your boat via the shore power earth wire. These currents can cause corrosion to the boat’s underwater metals, like the hull, propeller, shaft and so on. The galvanic isolator consists of two diodes connected in antiparallel. The galvanic isolator is connected between the shore earth connection and the central earth point in the boat.

The diodes in this configuration conduct electricity in both directions only when a certain threshold voltage is reached. The threshold voltage is approximately 1.4 Vdc. The threshold voltage is higher than the galvanic potential difference between the various metals. In this way, no galvanic current can run. On the other hand, a higher earth fault voltage in the AC circuit will be allowed to pass through enabling the full functioning of a connected RCD. The advantage of the galvanic isolator is its low weight and size, the disadvantage is that this unit relies on a good earth conductor. Another consideration is that galvanic corrosion can also take place through the neutral conductor, this in cases where the neutral conductor has been connected to earth through one of the electrical appliances on board, like a suppression filter or other appliances. |

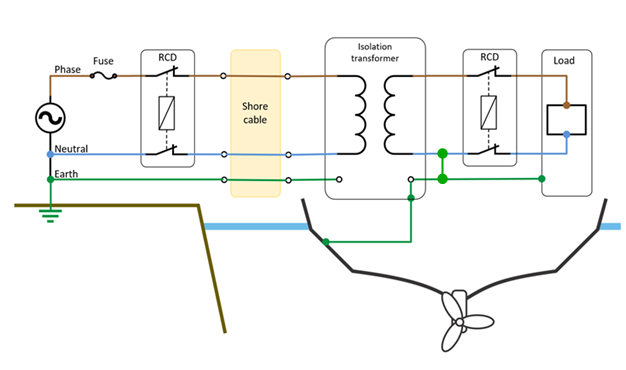

A better solution to stop galvanic corrosion is the use of an isolation transformer. In an isolation transformer, the incoming electricity is changed into electromagnetism and then changed back again into electricity.

The input and output are completely isolated and will break the electric circuit between star point - earth conductor - hull - water - star point, thus effectively blocking a galvanic current. Another feature of the isolation transformer is that electrically speaking it is an electricity source, fed by another electricity source. On the output side of the transformer, one of the outgoing phases is connected to the hull, thereby, creating a phase, neutral and earth, thus guaranteeing a correct functioning of an RCD. An isolation transformer will give the same safety as in a house installation and more. The installation is also completely isolated of electrical problems of surrounding boats. An added benefit is that an isolation transformer is quite often able to raise or lower the incoming shore voltage. This can be useful when a 230Vac boat has to connect to a 120Vac supply, or vice versa. |