- 5.1. VE.Bus Multis/Quattros/Inverters

- 5.2. AC load monitoring

- 5.3. Battery monitors, MPPTs, Orion XS and Smart IP43 Chargers with a VE.Direct port

- 5.4. VE.Can Devices

- 5.5. VE.Can Interfaces

- 5.6. Inverter RS, Multi RS and MPPT RS

- 5.7. BMV-600 series

- 5.8. DC Link Box

- 5.9. VE.Can Resistive Tank Sender Adapter

- 5.10. Connecting a GX Tank 140

- 5.11. Connecting hardwired Victron temperature sensors

- 5.12. Victron Energy Meter VM-3P75CT

- 5.13. EV Charging Station

For brevity, all Multis, Quattros, and Inverters are referred to as VE.Bus products.

Compatibility with GX devices

The earliest VE.Bus firmware supported by the VGX is 111.

he table below outlines compatibility based on the VE.Bus device’s microprocessor version:

VE.Bus device microprocessor | GX device support |

|---|---|

18xxxxxx | No |

19xx111 | Yes |

20xx111 | Yes |

26xxxxx | Yes |

27xxxxx | Yes |

Notes:

| |

Remote on/off terminal use

For Multis, Quattros and EasySolars:

It is not possible to use the Remote On/Off header with a GX device.

Keep the factory connection: wire between left and middle terminal.

If system disable is required, use the Safety Switch Assistant.

Note: The above limitation does not apply to: MultiPlus-II, Quattro-II, and EasySolar-II. They support Remote On/Off together with GX devices.

System connections

Caution

Do not confuse the VE.Bus ports on a GX device with the Ethernet or VE.Can/BMS-Can ports.

Single VE.Bus products

Connect to either VE.Bus port on the GX device.

Use standard RJ45 UTP cable (see pricelist).

Warning

Leave any unused VE.Bus ports open. Do not insert the blue RJ45 VE.Can terminators into these ports.

Parallel, split- and three-phase VE.Bus systems

To connect multiple VE.Bus products, configured as a parallel, split-phase or three-phase VE.Bus system, connect the first or last VE.Bus product in the chain to a GX device VE.Bus port.

Use standard RJ45 UTP cable (see pricelist).

Warning

Leave any unused VE.Bus ports open. Do not insert the blue RJ45 VE.Can terminators into these ports.

VE.Bus systems with Lithium batteries and VE.Bus BMS (v1 only)

The following applies only to the VE.Bus BMS V1, not to be confused with its successors, the VE.Bus BMS V2 or VE.Bus BMS NG.

GX device connection

Connect the GX device to the MultiPlus/Quattro VE.Bus socket, not to the Remote panel socket.

Alternatively, connect to one of the Multis/Quattros in the system.

Combining MultiPlus/Quattro with a VE.Bus BMS and a Digital Multi Control is possible. Simply connect the Digital Multi Control to the RJ45 socket on the VE.Bus BMS labelled Remote panel.

Limitations

The On/Off/Charger Only control will be disabled automatically in the GX device menu when a VE.Bus BMS is detected.

Combining a MultiPlus/Quattro with a VE.Bus BMS and a Digital Multi Control is possible. Simply connect the Digital Multi Control to the RJ45 socket on the VE.Bus BMS labelled Remote panel.

Input current limit settings remain available via the GX device, even with a VE.Bus BMS.

Auto power-down on low battery

To enable auto power-down in the GX device on low battery:

Connect the Power in V+ terminal on the GX device to the Load Disconnect output of the VE.Bus BMS.

Ensure both the GX device and the VE.Bus BMS share the same battery negative (GND).

Combining the VGX with a Digital Multi Control

Both a GX device and a Digital Multi Control (DMC) can be connected to the same VE.Bus system. However, please note:

The On/Off and Charger Only controls on the GX device are disabled when a DMC is present.

The input current limit is set via the Digital Multi Control. This setting takes precedence and overrides the GX device. It cannot be adjusted from the GX device in this configuration.

Connecting multiple VE.Bus systems to a single VGX

Only one VE.Bus system can be connected directly to the GX device’s built-in VE.Bus ports. To connect additional systems, consider the following options:

Option 1: Use an MK3-USB interface

This method allows multiple systems to be visible, but with limited functionality:

Only the system connected to the built-in VE.Bus ports contributes data to the Overview pages.

All connected systems appear in the Device List and are included in VRM energy statistics.

DVCC and ESS control applies only to the system connected directly to the built-in VE.Bus ports.

AdditionalsSystems connected via MK3-USB do not support DVCC control and will follow their own internal configuration for charging/discharging.

Generator start/stop logic applies only to the directly connected system.

For ESS systems, only the system on the built-in VE.Bus ports participates in ESS mechanisms. Others are visible in the Device List only.

Option 2: Use VE.Bus to VE.Can Interface (ASS030520105)

Not recommended - this is a deprecated product.

Requires one interface per VE.Bus system.

VE.Can must be properly terminated and powered. For more details, refer to the data communication whitepaper, Q17.

Additional features provided by a GX device to VE.Bus products

When connected to the internet, the GX device enables the following:

Remote configuration via VRM – see Remote VE.Configure manual for more information, system requirements and specific steps to access this feature.

Remote VE.Bus firmware updates – see Remote VE.Bus Firmware Updates Manual.

All supported energy meter types can be assigned the role of AC meter.

To do this, go to: Settings → Energy meters → [your_energy_meter] → Role and select AC meter as the role (alternatives include Grid, PV Inverter, and Generator).

Note

Please note that such metered loads are not used in any calculations, just monitoring.

Devices with a VE.Direct port, such as BMV battery monitors, MPPT solar chargers, Orion XS, and Smart IP43 Chargers, can be directly connected to a GX device via VE.Direct.

There are two VE.Direct cable types available:

Straight VE.Direct cables - Part no. ASS030530xxx

Right-angle VE.Direct cables - Part no. ASS030531xxx, designed to minimise depth behind mounting panels

Note

VE.Direct cables have a maximum length of 10 m and cannot be extended. For longer distances, use a VE.Direct to USB interface with an active USB extension cable.

VE.Direct to VE.Can interface (limited use)

The VE.Direct to VE.Can interface can be used only with:

BMV-700

BMV-702

Not compatible with:

Not compatible with:

BMV-712

MPPT solar chargers

VE.Direct inverters

This interface does not convert data for those devices into CAN-bus messages.

If using the VE.Direct to VE.Can interface:

Ensure the VE.Can network is terminated and powered.

Refer to Q17 in the Victron Data Communication Whitepaper for powering instructions.

Note

This interface is deprecated and not recommended for new installations.

Connecting more VE.Direct devices to your Venus GX than physical VE.Direct Ports

If you need to connect more VE.Direct devices than there are VE.Direct ports, the following options are available:

Use the VE.Direct to USB interface.

Use a USB hub if more ports are required.

Please refer to the Oveview of connections section for details on the maximum number of VE.Direct devices that can be connected.

Notes on older VE.Direct MPPTs

Some older models, like the MPPT 70/15, are not compatible with GX devices unless they meet a minimum hardware revision:

The device must be from year/week 1308 or later.

Firmware updates will not resolve incompatibility with earlier models.

To identify your model:

Check the serial number printed on the rear label.

Example: HQ1309DER4F means 2013, week 09, which is compatible.

You can use a SmartShunt or BMV-712 to monitor individual DC circuits rather than the entire battery system. To do this, change the Monitor mode setting from Battery Monitor to DC Energy Meter using VictronConnect.

Available DC meter types

Once DC Energy Meter mode is selected, the following types can be assigned in VictronConnect:

Sources: Solar charger, Wind charger, Shaft generator, Alternator, Fuel cell, Water generator, DC-DC charger, AC charger, Generic source

Loads: Generic load, Electric drive, Fridge, Water pump, Bilge pump, DC system, Inverter, Water heater

Integration with GX devices

When connected to the Venus GX, the selected meter type along with current (A) and power (W) is displayed in the user interface and sent to the VRM Portal for remote monitoring.

Special case: Type "DC System"

When configured as type “DC System”, the VGX offers extended functionality beyond data logging:

The DC System power display aggregates readings from all SmartShunts configured with the DC System type. This supports multi-location systems, for example, DC systems in both hulls of a catamaran.

DVCC Charge Current Limiting is dynamically adjusted: The GX device compensates for DC loads when setting charge current limits for Multis, Quattros, and Solar Chargers. For example:

If a DC load of 50 A is being measured

And the battery reports a CCL (Charge Current Limit) of 25 A

Then the system sets a limit of 75 A to the charging sources → Resulting in optimised charging behaviour for Yachts, RVs, Coaches, and other systems with significant DC loads.

Notes and limitations:

This feature is supported only by SmartShunt and BMV-712. It is not available on BMV-700 or BMV-702.

The Monitor mode must be configured using VictronConnect directly on the SmartShunt or BMV-712. For setup instructions, refer to the BMV-712 or SmartShunt product manual on the Battery Monitor product page

The NMEA2000-out feature does not support the DC meter types. For example, if a SmartShunt is configured to monitor an alternator, that data will not be available via NMEA 2000.

To connect a product with a VE.Can port, use a standard RJ45 UTP cable (available with straight and elbow connectors).

Important:

Terminate the VE.Can network at both ends using VE.Can terminator. A bag with two terminators is included with each VE.Can product. Additional terminators are available separately.

Compatibility notes

The MPPT 150/70 must be running firmware v2.00 or newer to function with GX devices

A Skylla-i control panel and an Ion Control panel can be used together with GX devices

All VE.Can devices provide power to the VE.Can network, so no separate VE.Can power supply is required

Protocol converters (e.g. VE.Bus to VE.Can interface, BMV to VE.Can interface) do not power the VE.Can network

VictronConnect-Remote (VC-R) support

The following VE.Can products support VictronConnect-Remote (VC-R), enabling configuration and monitoring via VRM.. For more details, refer to the VictronConnect manual.

VE.Can product | VC-R | Remarks |

|---|---|---|

Lynx Shunt VE.Can | Yes | - |

Lynx Smart BMS, Lynx BMS NG | Yes | - |

Inverter RS, Multi RS and MPPT RS | Yes | They also have VE.Direct but must be connected via VE.Can for VC-R |

Blue/Smart Solar VE.Can MPPTs [1] | Yes | Tr and MC4 models |

Skylla-i and Skylla-IP44/-IP65 | Yes | Requires firmware v1.11 |

[1] All VE.Can solar chargers except the very old (big rectangular case with display) BlueSolar MPPT VE.Can 150/70 and 150/85 | ||

The Venus GX has two fully functional VE.Can ports. They are independent from a data and connected device perspective. One is labelled VE.Can and is isolated, the other is labelled Can 2 and is non-isolated.

2 × Fully configurable VE.Can ports (VE.Can 1 is isolated)

Both ports can be set to:

VE.Can (250 kbit/s, default)

BMS-Can (500 kbit/s)

CAN-bus BMS (250 kbit/s)

Other supported CAN profiles such as RV-C

Usage guideline

VE.Can (250 kbit/s, default)

For Victron devices like:

VE.Can MPPTs

Skylla-IP65

Lynx Shunt VE.Can

Lynx Smart BMS and Lynx Smart BMS NG

Terminate both ends using the included VE.Can terminators

BMS-Can (500 kbit/s)

For managed lithium batteries (e.g. BYD, Pylontech, Freedomwon)

Terminate at the Cerbo GX with the included terminator

Follow the battery manufacturer’s instructions for termination on the battery side

Important

VE.Can and BMS-Can must not share the same bus

If both are needed, use a GX device with two separate CAN buses (e.g. Cerbo GX MK2 or Ekrano GX)

Port configuration

Access via Remote Console:

Settings → Services → VE.Can Port 1 / 2 → CAN-bus Profile

Default settings:

VE.Can: 250 kbit/s

Notes

Some BMS units use CANbus BMS profile at (250 kbit/s). Connect these to a VE.Can port and set the appropriate profile (VE.Can & CAN-bus BMS (250 kbit/s).

Only use batteries listed on Victron’s compatibility list to ensure proper communication. Others are not supported.

The Inverter RS, Inverter RS Solar, and Multi RS are equipped with both VE.Direct and VE.Can interfaces. However, for these products:

A GX device must be connected via VE.Can.

VE.Direct cannot be used to connect these devices to a GX system.

The VE.Direct interface on these models is intended solely for programming, using a VE.Direct to USB adapter.

Exception: MPPT RS

The MPPT RS can be connected to a GX device via either VE.Direct or VE.Can, depending on system requirements and available ports.

Connect the BMV-600 using the VE.Direct to BMV-60xS cable. (ASS0305322xx).

Connect the DC Link Box with the supplied RJ12 cable. Then connect the BMV-700 to the VGX.

See the VE.Can resistive tank sender adapter product page for details about the adapter.

Connection guidelines

Use a standard RJ45 RJ45 UTP cable to connect the adapter to a VE.Can network.

Terminate the VE.Can network at both ends using VE.Can terminators.

A bag with two terminators is included with each VE.Can product.

Additional terminators are available separately (Part No. ASS030700000).

Ensure that the CAN-bus is powered.

Refer to the Power chapter in the Tank Sender Adapter manual for details.

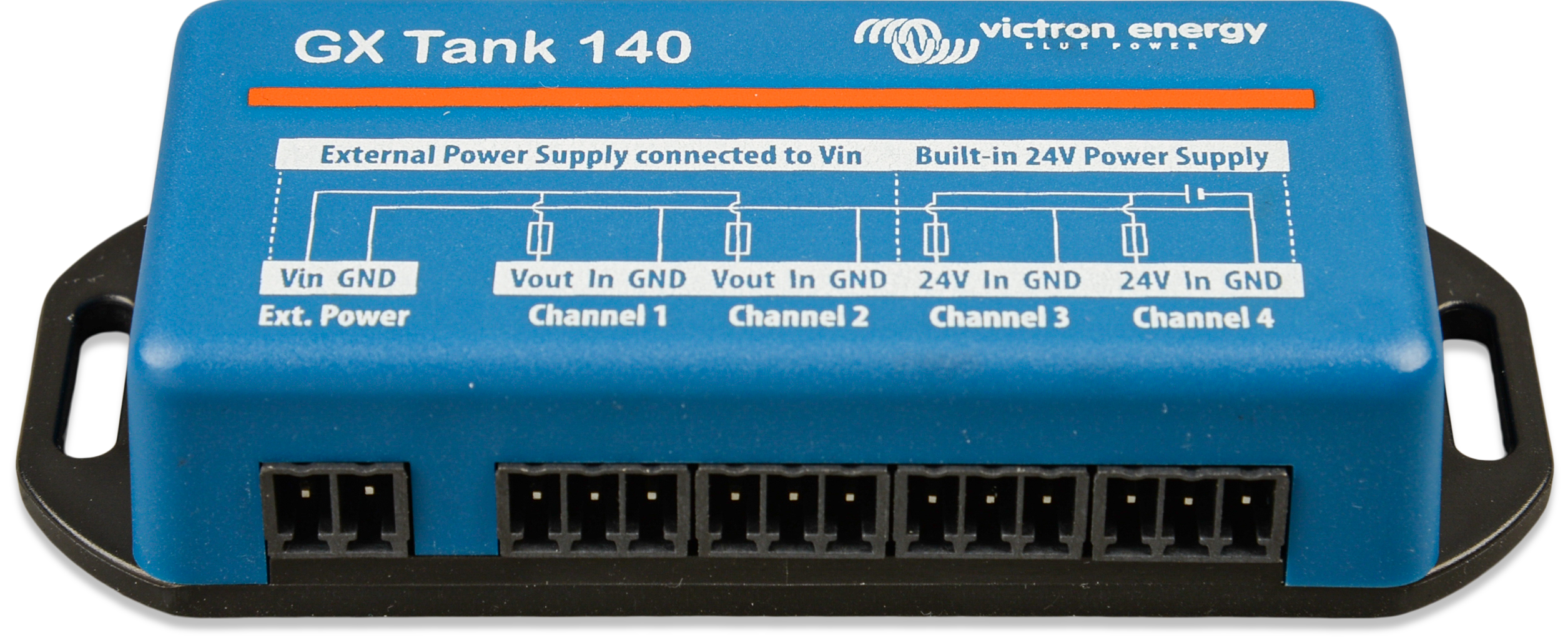

The GX Tank 140 is an accessory for the Victron GX range of system monitoring products. It supports up to four tank-level sensors, with readings visible locally on the GX device and remotely via the VRM Portal.

Input compatibility The GX Tank 140 supports:

Connection and power

Configuration options

For full technical details, refer to the documentation available on the GX Tank 140 product page. |  |

Victron temperature sensors can be used to measure and monitor various temperature sources, not limited to batteries. The supported measurement range is –40 °C to +70 °C.

See the Connection Overview for the location and number of temperature sensor inputs.

Compatible sensor

The correct sensor to use is: ASS000001000 – Temperature Sensor for Quattro, MultiPlus, and GX Devices

Note: This is not the same as the BMV temperature sensor accessory, which is not compatible with these inputs.

Additional notes

Although the sensor resembles a battery lug, it does not need to be installed on a battery.

Sensors are not included with the GX device and must be ordered separately.

Physical connection of temperature sensors

To connect the temperature sensors:

Prepare the sensor wire with either a ferrule or at least 10 mm of exposed copper.

Insert the wire into the appropriate screw terminal and tighten securely.

Wire polarity

Red wire → Connect to the terminal marked Temp 1 or Temp 2

Black wire → Connect to the terminal marked GND

Sensors are enabled (and disabled) in the Settings → I/O → Analog inputs menu of the GX device settings. Once enabled, temperature sensor data is visible in the device list, and also logged to VRM. Note: The Ekrano GX and Venus GX have two temperature inputs, while the Cerbo GX has four. |

Selecting the temperature sensor from the device list menu displays an overview of the sensor’s status and current temperature. The overview also includes two submenus: one for sensor setup and another for the device menu. The temperature type can be changed in the Setup menu. The available options are Battery, Fridge, or Generic. An offset can be applied to correct the reading, and the scale can be adjusted using a multiplier between 1 and 10. Additionally, the sensor voltage can be monitored. The device menu provides general information about the sensor and allows you to assign a custom name for easier identification when multiple sensors are in use. |

The Victron VM-3P75CT is a versatile energy meter for monitoring single-phase and three-phase power and energy consumption. It can be used to measure:

Grid connection (at the distribution box)

PV inverter output

Generator (AC genset) output

Inverter or inverter/charger output

The meter calculates power values for each phase and transmits the data at a high refresh rate over VE.Can or Ethernet.

Key features

Dual communication options: VE.Can and Ethernet

Compatible with GX devices such as the Cerbo GX and Ekrano GX

Data is viewable on the GX device, VictronConnect, and the VRM Portal

Split-core current transformers for easy, non-intrusive installation

Installation

Follow the setup procedure as described in the VM-3P75CT energy meter manual.

Ensure the energy meter is on the same local network as the GX device when using Ethernet.

VE.Can connection: Plug-and-play. No manual activation required.

Ethernet connection: After initial installation, the energy meter must be activated:

In the GX device menu, go to Settings → Modbus TCP/UDP devices → Discovered devices and enable the discovered energy meter; it's disabled by default when first installed and powered. | |

The VM-3P75CT then becomes visible in the Device List and can be monitored from there. For more details, see the energy meter manual. |

The EV Charging Station and EV Charging Station NS, with both three-phase and single-phase charging capabilities, integrate seamlessly into the Victron environment via a GX device connection over WiFi. Operation and monitoring are easily managed via Bluetooth using the VictronConnect App.

Set up and configure the EVCS according to the instructions in the EV Charging Station manual. Ensure that:

Communication with the GX device is enabled.

The EVCS and GX device are connected to the same local network.

GX device setup

Note: EV Charging Stations connected before updating the GX device to firmware version 3.12 will be activated automatically. New devices must be enabled manually via the above menu. In the GX device menu, go to Settings → Services → Modbus TCP and enable Modbus TCP. Once activated, the EVCS will appear in the Device list, where it can be monitored and controlled. For further details, refer to the EV Charging Station Manual. | |