Then, single, multiple or a combination of Lynx Distributor modules and/or Lynx Power In/Lynx Class-T Power In modules are added.

Together they form a continuous negative and positive busbar with DC connections and, depending on the configuration, integrated fuses, a battery monitor and/or lithium battery management.

Each Lynx module can be connected to other Lynx modules on the left and right. Note that M10 modules cannot be connected directly to M8 modules and vice versa.

If the Lynx module is the first in line, the last in line or is used by itself, it is possible to connect batteries, loads or chargers directly to these connections. Please note that additional fusing may be required if batteries and loads are connected directly to the interconnections.

If the Lynx System contains a Lynx Shunt VE.Can, the batteries always have to be connected to the left side of the Lynx System and the rest of the DC system (loads and chargers) connect to the right side. This so the battery state of charge can be correctly calculated.

Example of Lynx module orientation: the batteries connect to the left side and all loads and chargers connect on the right side

The Lynx modules can be mounted in any orientation. Should they be mounted upside down so that the text on the front of the units is upside down as well, use the special stickers included with each Lynx module so that the text is orientated the correct way.

Example of Lynx modules mounted upside down: the batteries connect to the right side, all loads and chargers connect to the left side and the upside-down stickers are affixed.

This system contains the following components:

Lynx Power In with 4 paralleled 12V lead acid batteries.

Identical cable lengths for each battery.

Lynx Shunt VE.Can with main system fuse and battery monitor.

Lynx Distributor with fused connections for inverter/charger(s), loads and chargers. Note that additional modules can be added if more connections are needed.

Cerbo GX (or other GX device) to read out the battery monitor data.

System with Lynx Shunt VE.Can, lead acid batteries and a Lynx Distributor

System with Lynx Shunt VE.Can, lead acid batteries and a Lynx Distributor

The Lynx Distributor, Lynx Shunt VE.Can, Lynx Class-T Power In and the Lynx Power In are rated for a nominal current of 1000A for 12, 24 or 48 System voltages.

See the table below for an idea of how much power the Lynx modules are rated at different voltages. The power rating will indicate how big the connected inverter/charger system can be. Remember that if inverters or inverter/chargers are used, the batteries will power both the AC and DC systems. Also, be aware that a Lynx Smart BMS or a Lynx Ion (now discontinued) can have a lower current rating.

12V | 24V | 48V | |

|---|---|---|---|

1000A | 12kW | 24kW | 48kW |

The Lynx Shunt VE.Can M10 model can accommodate a CNN or ANL fuse and also offers space for the supplied fuse dummy (piece of busbar) should the main fuse be installed outside the shunt. It is also possible to install a Mega fuse on the M6 bolts. At Victron we stock the 325 A/ 80 V CNN fuse (part number CIP140325000), but they are available in 35 A up tp 800 A from almost everywhere.

|

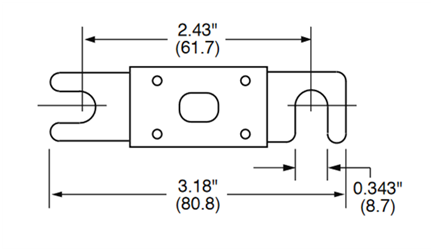

CNN fuse dimensions in inches (mm)

Always use fuses with the correct voltage and current rating. Match the fuse rating to the maximum voltages and currents that potentially can occur in the fused circuit. For more information on fuse ratings and fuse current calculations see the Wiring Unlimited book.

Caution

The total value of the fuses of all circuits should not be more than the current rating of the Lynx module or the Lynx model with the lowest current rating in case of multiple Lynx modules are used.

The current rating of the wires or cables used to connect the Lynx Shunt VE.Can (M10) to batteries and/or the DC loads, has to be rated for the maximum currents that can occur in the connected circuits. Use cabling with a sufficient core surface area to match the maximum current rating of the circuit.

For more information on cabling and cable thickness calculations, see our book, Wiring Unlimited.