Warning

This product may only be installed by a qualified electrical engineer.

Warning

This product is not suitable for direct connection to a vehicle's electrical system. It should be connected to a dedicated DC system that includes a dedicated service or house battery, appropriate fusing, and the appropriate gauge of DC wiring. For recommendations on battery capacity, fuse rating, and cable gauge, refer to Chapter .. in this manual."

The product must be installed in a dry and well-ventilated area, as close as possible to the batteries. There should be a clear space of at least 10 cm around the appliance for cooling.

Warning

Excessively high ambient temperature will result in the following:

Reduced service life.

Reduced charging current.

Reduced peak capacity, or shutdown of the inverter.

Never position the appliance directly above the batteries.

The inverter/charger is suitable for wall mounting. A solid surface, suitable for the weight and dimensions of the product must be available (e.g., concrete, or masonry). For mounting purposes, a hook and two holes are provided at the back of the casing (see appendix G).

Warning

The interior of the product must remain accessible after installation.

Try and keep the distance between the product and the battery to a minimum in order to minimize cable voltage losses.

Warning

For safety purposes, this product should be installed in a heat-resistant environment. You should prevent the presence of e.g. chemicals, synthetic components, curtains or other textiles, etc., in the immediate vicinity.

Warning

Each system requires a method of disconnecting the AC and DC circuits. If the overcurrent protection device is a circuit breaker, it will also serve as the disconnect. If fuses are used, separate disconnect switches will be needed between the source and the fuses.

Warning

To reduce the risk of fire, do not connect to an ac load center (circuit breaker panel) having multiwire branch circuits connected.

Warning

CAUTION – To reduce risk of injury, charge only Lead Acid or LIFEPO4 type rechargeable batteries. Other types of batteries may burst causing personal injury and damage. Do not try to recharge non-rechargeable batteries.

Warning

Use of an attachment not recommended or sold by the marine unit manufacturer may result in a risk of fire, electric shock, or injury to persons

Warning

WARNING – RISK OF EXPLOSIVE GASES) WORKING IN VICINITY OF A LEAD-ACID BATTERY IS DANGEROUS. BATTERIES GENERATE EXPLOSIVE GASES DURING NORMAL BATTERY OPERATION. FOR THIS REASON, IT IS OF UTMOST IMPORTANCE THAT EACH TIME BEFORE SERVICING THE UNIT IN THE VICINITY OF THEBATTERY, YOU READ THIS MANUAL AND FOLLOW THE INSTRUCTIONS EXACTLY.

PERSONAL PRECAUTIONS

Someone should be within range of your voice or close enough to come to your aid when you work near a lead-acid battery

Have plenty of fresh water and soap nearby in case battery acid contacts skin, clothing, or eyes.

Wear complete eye protection and clothing protection. Avoid touching eyes while working near battery.

If battery acid contacts skin or clothing, wash immediately with soap and water. If acid enters eye, immediately flood eye with running cold water for at least 10 min and get medical attention immediately.

NEVER smoke or allow a spark or flame in vicinity of battery or engine.

Be extra cautious to reduce risk of dropping a metal tool onto battery. It might spark or short-circuit battery or other electrical part that may cause explosion.

Remove personal metal items such as rings, bracelets, necklaces, and watches when working with a lead-acid battery. A lead-acid battery can produce a short-circuit current high enough to weld a ring or the like to metal, causing a severe burn.

NEVER charge a frozen battery.

If necessary to remove battery from vessel, always remove grounded terminal from battery first. Make sure all accessories in the vessels are off, so as not to cause an arc.

Be sure area around battery is well ventilated. Clean battery terminals. Be careful to keep corrosion from coming in contact with eyes. Study all battery manufacturer’s specific precautions such as removing or not removing cell caps while charging and recommended rates of charge.

Clean battery terminals. Be careful to keep corrosion from coming in contact with eyes.

Study all battery manufacturer’s specific precautions such as removing or not removing cell caps while charging and recommended rates of charge.

Warning

MARINE UNIT LOCATION

Locate marine unit away from battery in a separate, well ventilated compartment

Never place marine unit directly above battery; gases from battery will corrode and damage marine unit.

Never allow battery acid to drip on marine unit when reading gravity or filling battery.

Do not operate marine unit in a closed-in area or restrict ventilation in any way.

Warning

DC CONNECTION PRECAUTIONS

Connect and disconnect DC output connections only after setting any marine unit switches to off position and removing AC cord from electric outlet or opening AC disconnect.

Warning

EXTERNAL CONNECTIONS TO CHARGER SHALL COMPLY WITH THE UNITED STATES COAST GUARD ELECTRICAL REGULATIONS (33CFR183, SUB PART I).

Warning

GROUNDING INSTRUCTIONS – This marine unit should be connected to a grounded, metal, permanent wiring system; or an equipment-grounding conductor should be run with circuit conductors and connected to equipment-grounding terminal or lead on unit. Connections to unit should comply with all local codes and ordinances

Warning

This product is not suitable for direct connection to a vehicle's electrical system. It should be connected to a dedicated DC system that includes a dedicated service or house battery, appropriate fusing, and the appropriate DC wiring gauge. For recommendations on battery capacity, fuse rating, and cable gauge, refer to Chapter Connection of battery cables in this manual."

Caution

CAUTION

When integrating inverter/chargers with generators in a single enclosure (hybrid generators), using shock mounts is mandatory. They mitigate damage risk to the inverter/charger by absorbing the generator's operational energy, thus extending component lifespan.

Key criteria for selecting shock mounts include:

Selection is based on the specific generator vibration frequency ranges to be isolated.

The shock mounts must bear the equipment's weight without impairing functionality.

To fully utilize the product's capacity, ensure the use of batteries with adequate capacity, an appropriate DC fuse, and battery cables of sufficient cross-section. DC cables should be copper, with a 90ºC (194ºF) rating. Refer to the table below for sizing recommendations.

In Canada, battery installation should be in accordance with the storage battery rules of the Canadian Electrical Code, Part I.

Model | Battery capacity | DC fuse | Cross-section per positive and negative terminal connection for cables between 0 and 5m *, **, *** | Cross-section per positive and negative terminal connection for cables between 5 and 10m *, **, *** |

|---|---|---|---|---|

12/3000/120 | 400 - 1200Ah | 400A | 2x AWG 1/0 | 2x AWG 2/0 |

24/3000/70 | 200 - 700Ah | 300A | AWG 1/0 | 2x AWG 1/0 |

Size | Recommended cable lugs |

|---|---|

AWG 2/0 | Molex part no. 19221-0243 |

AWG 1/0 | Molex part no. 19221-0240 |

* Follow local installation rules.

** Do not locate battery cables in a closed conduit

*** “2x” means two positive and two negative cables.

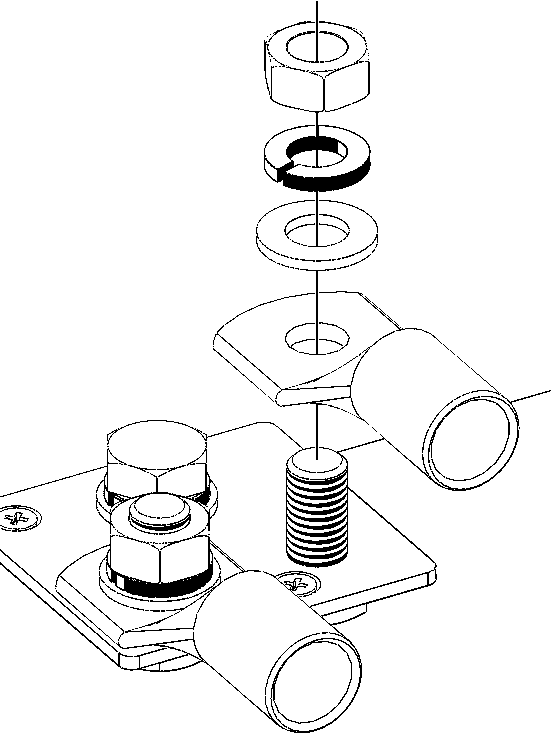

Connection procedure WarningUse a torque wrench with an insulated box spanner in order to avoid shorting the battery. Recommended torque: 12 Nm (M8 nut) Avoid shorting the battery cables. | ||

Proceed as follows to connect the battery cables:

|

| |

Notice

Internal resistance is an important factor when working with low-capacity batteries. Please consult your supplier or the relevant sections of our Energy Unlimited or Wiring Unlimited books. Both can be downloaded from our website.

Warning

This is a safety class I product (supplied with a ground terminal for safety purposes). Its AC input and/or output terminals and/or grounding point on the outside of the product must be provided with an uninterruptible grounding point for safety purposes.

This product is provided with a ground relay (relay H, see appendix B) that automatically connects the Neutral output to the chassis if no external AC supply is available. If an external AC supply is provided, the ground relay H will open before the input safety relay closes. This ensures the correct operation of an earth leakage circuit breaker connected to the output.

In a fixed installation, an uninterruptable grounding can be secured by means of the grounding wire of the AC input. Otherwise, the casing must be grounded.

In a mobile installation (for example, with a shore current plug), interrupting the shore connection will simultaneously disconnect the grounding connection. In that case, the casing must be connected to the chassis (of the vehicle) or to the hull or grounding plate (of the boat).

The inverter incorporates a mains frequency isolating transformer. This precludes the possibility of DC current at any AC port. Therefore, type A RCDs can be used.

In case of a boat, direct connection to the shore ground is not recommended because of potential galvanic corrosion. The solution to this is using an isolation transformer.

Warning

This unit or system is provided with fixed trip limits and shall not be aggregated above 30kW on a single point of common connection.

The AC terminal blocks can be found on the printed circuit board, see Appendix A.

Do not invert neutral and phase when connecting the AC.

The AC connections need to be made with three-wire 90ºC (194ºF) copper cable.

Quattro-II 2x120V - 3k models | AC-in 1 | AC-in 2 | AC-Out-1 | AC-Out-2 |

|---|---|---|---|---|

Rated current | 50 A | 50 A | 75 A | 50 A |

Recommend fuse or circuit breaker | 50 A | 50 A | 75 A | 50 A |

Minimum wire gauge | AWG 6 | AWG 6 | AWG 6 | AWG 6 |

Ferrule pin and stripping length | 0.7 inch (18 mm) | 0.7 inch (18 mm) | 0.7 inch (18 mm) | 0.7 inch (18 mm) |

AC-in-1

One AC input cable can be connected to the terminal block ‘AC-in-1’. If AC voltage is present on these terminals, the inverter/charger will use this connection. Generally a generator will be connected to AC-in-1.

From left to right: “L2” (phase 2), “N” (neutral), “PE” (earth) and “L” (phase).

The AC-in-1 input must be protected by a fuse or magnetic circuit breaker rated at 50A or less, and cable cross-section must be sized accordingly. If the input AC supply is rated at a lower value, the fuse or magnetic circuit breaker should be downsized accordingly.

AC-in-2

A second AC input cable can be connected to the terminal block ‘AC-in-2’. If AC voltage is present on these terminals, the inverter/charger will use this connection unless voltage is also present on AC-in-1. The Quattro will then automatically select AC-in-1. Generally, the mains supply or shore voltage will be connected to AC-in-2.

From left to right: “L2” (phase 2), “N” (neutral), “PE” (earth) and “L” (phase).

The AC-in-2 input must be protected by a fuse or magnetic circuit breaker rated at 50A or less, and cable cross-section must be sized accordingly. If the input AC supply is rated at a lower value, the fuse or magnetic circuit breaker should be downsized accordingly.

Note: The inverter/charger may not start when AC is present only on AC-in-2, and DC battery voltage is 10% or more below nominal (less than 22 Volt in case of a 24 Volt battery).

Solution: connect AC power to AC-in-1, or recharge the battery.

AC-out-1

The AC output cable can be connected directly to the terminal block ‘AC-out’.

From left to right: “L2” (phase 2), “N” (neutral), “PE” (earth) and “L” (phase).

With its PowerAssist feature the inverter/charger can add up to 3 kVA (that is 3000 / 120 = 25 A) to the output during periods of peak power requirement. Together with a maximum input current of 50 A this means that the output can supply up to 50 + 25 = 75 A.

An earth leakage circuit breaker and a fuse or circuit breaker rated to support the expected load must be included in series with the output, and cable cross-section must be sized accordingly.

AC-out-2

A second output is available that disconnects its load in the event of battery operation. On these terminals, equipment is connected that may only operate if AC voltage is available on AC-in-1, e.g. an electric boiler or an air conditioner. The load on AC-out-2 is disconnected immediately when the inverter/charger switches to battery operation. After AC power becomes available on AC-in-1, the load on AC-out-2 will be reconnected with a delay of approximately 2 minutes. This to allow a genset to stabilise.

From left to right: “L2” (phase 2), “N” (neutral), “PE” (earth) and “L” (phase).

A number of optional connections are possible:

The product can be remotely controlled in two ways.

With an external switch connected to the "Remote on/off connector" terminal (see Appendix A). Operates only if the switch on the inverter/charger is set to “on”.

With a Digital Multi Control panel connected to one of the two VE.Bus RJ45 sockets (see Appendix A). Operates only if the switch on the inverter/charger is set to “on”.

See Appendix A for the location of the connector.

The product is equipped with a programmable relay.

The relay can be programmed for all kinds of other applications however, for example as a starter relay for a generator.

See Appendix A for the location of the connector.

The product is equipped with 2 analogue/digital input/output ports.

These ports can be used for several purposes. One application is communication with the BMS of a lithium-ion battery.

See Appendix A for the location of the connector.

The 12 and 24V models have a connection for charging a starter battery. Output current is limited to 4A.

See Appendix A for the location of the connector.

For compensating possible cable losses during charging, two sense wires can be connected with which the voltage directly on the battery or on the positive and negative distribution points can be measured. Use wire with a cross-section of 0.75mm² (AWG 18).

During battery charging, the inverter/charger will compensate the voltage drop over the DC cables up to a maximum of 1 Volt (i.e. 1V over the positive connection and 1V over the negative connection). If the voltage drop threatens to become larger than 1V, the charging current is limited in such a way that the voltage drop remains limited to 1V.

See Appendix A for the location of the connector.

For temperature-compensated charging, the temperature sensor (supplied with the inverter/charger) can be connected. The sensor is isolated and must be fitted to the negative terminal of the battery.

See Appendix A for the location of the connector.

Up to six identical units, can be connected in parallel. When connecting inverter/charger units in parallel, the following requirements must be met:

All units must be connected to the same battery.

A maximum of six units can be connected in parallel.

Only identical devices may be connected in parallel.

The DC connection cables to the devices must be of equal length and cross-section.

If a positive and a negative DC distribution point is used, the cross-section of the connection between the batteries and the DC distribution point must at least equal the sum of the required cross-sections of the connections between the distribution point and the inverter/charger units.

Place the inverter/charger units close to each other, but allow at least 10cm for ventilation purposes under, above and beside the units.

UTP cables must be connected directly from one unit to another (and to the remote panel). Connection or splitter boxes are not permitted.

Always interconnect the negative battery cables before placing the UTP cables.

Only one remote control means (panel or switch) can be connected to the system.

The inverter/charger can also be used in a 3-phase wye (Y) configuration. To this end, the devices are connected by means of standard RJ45 UTP cables (the same as for parallel operation). The system of inverter/chargers (and the optional Digital Multi Control panel) will require subsequent configuration (see the Configuration chapter.

For prerequisites, see the Parallel connection chapter.

Notice

The inverter/charger is unsuitable for a three-phase delta (Δ) configuration.

The L2 outputs are disabled in a multi-phase setup.

Strings of paralleled units can be connected in three phases.